Effect of Quenching Temperature on Sulfide Stress Cracking Behavior of Martensitic Steel

Qian Wang, Yu Sun, Shunjie Gu, Zaoneng He, Qingfeng Wang, Fucheng Zhang

Index: 10.1016/j.msea.2018.03.063

Full Text: HTML

Abstract

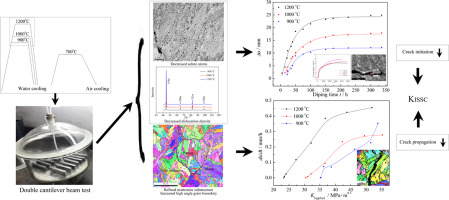

A medium-carbon Cr-Mo-V martensitic steel was quenched at a decreased temperature from 1200 to 900 °C and tempered at an identical temperature of 700 °C, thus provided with an enhanced KISSC value. The effect of quenching temperature, Tq, on the sulfide stress cracking (SSC) behaviors was estimated via the double cantilever beam (DCB) and the electrochemical hydrogen permeation (EHP) tests, and the microstructure characterizations. The results indicate that, as the Tq decreased, the overall and local hydrogen concentration around the inclusions decreased, owing to the decreased solute atoms and dislocation density, therefore preventing the SSC initiation. Moreover, the martensitic microstructure were refined and the fraction of the high angle grain boundaries (HAGBs) increased with the decreased Tq, thus decreasing the SSC propagation rate by diverting more frequently the propagating direction and further hindering the SSC propagation. The overall SSC resistance of this martensitic steel was therefore significantly enhanced.

|

Microstructural evolution and improvement in mechanical prop...

2018-04-10 [10.1016/j.msea.2018.04.031] |

|

Effect of layered microstructure on the superplasticity of f...

2018-04-07 [10.1016/j.msea.2018.04.028] |

|

Metallic glass hardening after thermoplastic forming

2018-04-07 [10.1016/j.msea.2018.04.021] |

|

Strain rate sensitivity assessment of metallic materials by ...

2018-04-07 [10.1016/j.msea.2018.04.023] |

|

Detection of Intergranular Embrittlement of Reactor Pressure...

2018-04-04 [10.1016/j.msea.2018.04.008] |