7543-51-3

| 中文名 | 磷酸锌 |

|---|---|

| 英文名 | Zinc Phosphate Tetrahydrate |

| 英文别名 | trizinc,diphosphate,tetrahydrate |

| 密度 | 3.04 g/cm3 |

|---|---|

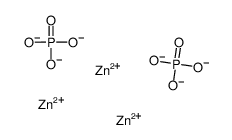

| 分子式 | O8P2Zn3 |

| 分子量 | 386.08300 |

| 精确质量 | 381.69400 |

| PSA | 192.12000 |

| LogP | 0.76450 |

| 外观性状 | Powder | white |

| 储存条件 | 密闭于阴凉干燥环境中 |

| 稳定性 | 遵照规定使用和储存则不会分解。在水中的溶解度随温度升高而下降,溶于稀酸和稀氨水。100℃时失去2分子结晶水,250℃时变成无水物。 |

| 水溶解性 | insoluble H2O, alcohol; soluble dilute mineral acids, acetic acid, ammonia solutions, alkali hydroxide solutions [MER06] |

| 分子结构 | 1、摩尔折射率:无可用 2、 摩尔体积(cm3/mol):无可用 3、 等张比容(90.2K):无可用 4、 表面张力(dyne/cm):无可用 5、 极化率:无可用 |

| 更多 | 1. 性状:无色斜方晶系的结晶,具有三种变体(相对密度分别为3.04、3.03和3.75)。 2. 密度(g/mL,25/4℃):3.3~3.9 3. 相对蒸汽密度(g/mL,空气=1):无可用 4. 熔点(ºC):无可用 5. 沸点(ºC,常压):无可用 6. 沸点(ºC,5.2kPa):无可用 7. 折射率:无可用 8. 闪点(ºC):无可用 9. 比旋光度(º):无可用 10. 自燃点或引燃温度(ºC):无可用 11. 蒸气压(kPa,25ºC):无可用 12. 饱和蒸气压(kPa,60ºC):无可用 13. 燃烧热(KJ/mol):无可用 14. 临界温度(ºC):无可用 15. 临界压力(KPa):无可用 16. 油水(辛醇/水)分配系数的对数值:无可用 17. 爆炸上限(%,V/V):无可用 18. 爆炸下限(%,V/V):无可用 19. 溶解性:无可用 |

|

Section 1: Product Identification Chemical Name:Zinc phosphate hydrate CAS Registry Number:7543-51-3 Formula:Zn3(PO4)2.XH2O EINECS Number:none Chemical Family:metal phosphate compound Synonym:Zinc phosphate tetrahydrate, Phosphoric acid zinc salt tetrahydrate

Section 2: Composition and Information on Ingredients IngredientCAS NumberPercentACGIH (TWA)OSHA (PEL) Title Compound7543-51-3100%no datano data Section 3: Hazards Identification Emergency Overview:Irritating to eyes, skin and respiratory tract. Moderate amounts may be harmful if swallowed. Primary Routes of Exposure:Ingestion, inhalation Eye Contact:Causes slight to mild irritation of the eyes. Skin Contact:Causes slight to mild irritation of the skin. Inhalation:Irritating to the nose, mucous membranes and respiratory tract. Ingestion:May cause abdominal pain, nausea, and vomiting. Irritating to skin, eyes and respiratory tract. Inhalation of dust may cause burning sensation, coughing, Acute Health Affects: wheezing, laryngitis, shortness of breath, headache, nausea and vomiting. May be harmful if swallowed. Chronic Health Affects:Prolonged or repeated exposure may cause breathing difficulty and decreased pulmonary function. NTP:No IARC:No OSHA:No SECTION 4: First Aid Measures Immediately flush the eyes with copious amounts of water for at least 10-15 minutes. A victim may need Eye Exposure: assistance in keeping their eye lids open. Get immediate medical attention. Wash the affected area with water. Remove contaminated clothes if necessary. Seek medical assistance if Skin Exposure: irritation persists. Remove the victim to fresh air. Closely monitor the victim for signs of respiratory problems, such as difficulty Inhalation: in breathing, coughing, wheezing, or pain. In such cases seek immediate medical assistance. Seek medical attention immediately. Keep the victim calm. Give the victim water (only if conscious). Induce Ingestion: vomiting only if directed by medical personnel. SECTION 5: Fire Fighting Measures Flash Point:not applicable Autoignition Temperature:none Explosion Limits:none Extinguishing Medium:none required If involved in a fire, fire fighters should be equipped with a NIOSH approved positive pressure self-contained Special Fire Fighting Procedures: breathing apparatus and full protective clothing. Hazardous Combustion andNone Decomposion Products: Unusual Fire or Explosion Hazards: No unusual fire or explosion hazards. SECTION 6: Accidental Release Measures Spill and Leak Procedures:Small spills can be mixed with powdered sodium carbonate or ground limestone and swept up. SECTION 7: Handling and Storage Handling and Storage:Store material in a tightly sealed bottle away from moisture. SECTION 8: Exposure Controls and Personal Protection Eye Protection:Always wear approved safety glasses when handling a chemical substance in the laboratory. Skin Protection:Wear appropriate chemical resistant gloves and protective clothing. Ventilation:If possible, handle the material in an efficient fume hood. In the absence of adequate ventilation a respirator should be worn. The use of a respiratory requires a Respirator: Respirator Protection Program to be in compliance with 29 CFR 1910.134. Ventilation:If possible, handle the material in an efficient fume hood. Additional Protection:No additional protection required. SECTION 9: Physical and Chemical Properties Color and Form:white pwdr. Molecular Weight:386.05 Melting Point:no data Boiling Point:no data Vapor Pressure:no data Specific Gravity:3.04 Odor:none Solubility in Water:insoluble SECTION 10: Stability and Reactivity Stability:air and moisture stable Hazardous Polymerization:no hazardous polymerization Conditions to Avoid:none Incompatibility:Active metals Decomposition Products:none SECTION 11: Toxicological Information RTECS Data:No information available in the RTECS files. Carcinogenic Effects:no data Mutagenic Effects:no data Tetratogenic Effects:no data SECTION 12: Ecological Information Ecological Information:No information available SECTION 13: Disposal Considerations Disposal:Dispose of according to local, state and federal regulations. SECTION 14: Transportation Shipping Name (CFR):Non-hazardous Hazard Class (CFR):NA Additional Hazard Class (CFR):NA Packaging Group (CFR):NA UN ID Number (CFR):NA Shipping Name (IATA):Non-hazardous Hazard Class (IATA):NA Additional Hazard Class (IATA):NA Packaging Group (IATA):NA UN ID Number (IATA):NA SECTION 15: Regulatory Information TSCA:Not listed in the TSCA inventory. SARA (Title 313):Title compound: see category code N982 for reporting Second Ingredient:none SECTION 16 - ADDITIONAL INFORMATION N/A |

|

生态学数据: 该物质对环境可能有危害,对水体应给予特别注意。

|

| 风险声明 (欧洲) | R36/37/38 |

|---|---|

| 安全声明 (欧洲) | 22-36/37/39 |

| 海关编码 | 2835299000 |

| 海关编码 | 2835299000 |

|---|